Submicron particle exposure in a fire station in Austin, Texas

By Brent Stephens on May 7, 2012

Last week I assisted a team of graduate students during a visit to a fire station in Austin, TX. The students were from Dr. Atila Novoselac‘s Energy and Indoor Air Quality Field Measurements course at the University of Texas at Austin. The students were measuring concentrations of particulate matter in the station in order to assess firefighters’ exposures to diesel exhaust.

These firefighters typically work 24-hour shifts. They eating, sleep, and exercise in the station during periods when they are not addressing emergencies outside of the station. In this particular station, the firemen share joint living facilities on the first floor, sleep in a big room of bunks on the second floor, which is connected via fire pole to the truck bay, where a large fire engine and the chief’s pick-up truck are stored. Interestingly, their exercise equipment is located inside the truck bay (including weights, benches, and even ping pong tables). The fighters are required to exercise 1-hour out of their 24-hour shifts.

Several measurements had previously been made in this particular station during a study by UT graduate students a few years ago. The Austin Fire Department (AFD) was worried about their firefighters’ exposures to diesel exhaust while living and working in the fire stations. At that time, only a couple of AFD stations had dedicated exhaust fans installed to vent fumes from the truck bays. AFD later won a grant to install special exhaust systems on nearly all of their fire stations (the particular system they use is called PlymoVent and shown below).

These systems include a large fan installed just outside the building which draws air from the truck bay through a series of flexible ducts. The ducts attach directly (magnetically) onto the exhaust pipes of the trucks whenever they arrive at the bay and remain connected until they drive off for a call. The fans turn on for about three minutes anytime they are first attached (which should actively exhaust direct diesel emissions while engines run) and remain connected while the trucks sit there (which should passively exhaust other fumes that may escape).

Now that exhaust systems are installed in the majority of fire stations in Austin, a group of students did a short follow-up study to measure the effectiveness of these exhaust systems in removing diesel exhaust. In this short study, we measured submicron particle concentrations using a condensation particle counter, which give total number concentrations of particles ~20 nanometers to ~1 micrometer in size. Those sizes are generally representative of smaller ultrafine particles, such as those found in diesel exhaust. We used these instruments to measure particle concentrations with and without the exhaust system installed in one fire station in two particular locations: (1) downstairs in the truck bay (directly behind the truck, near the exercise equipment) and (2) upstairs in the sleeping quarters. Measurements were made during a trial run where the fire station pretended to get a call. They started the engine inside the bay, drove off, circled the block, and reentered the station about 5 minutes later.

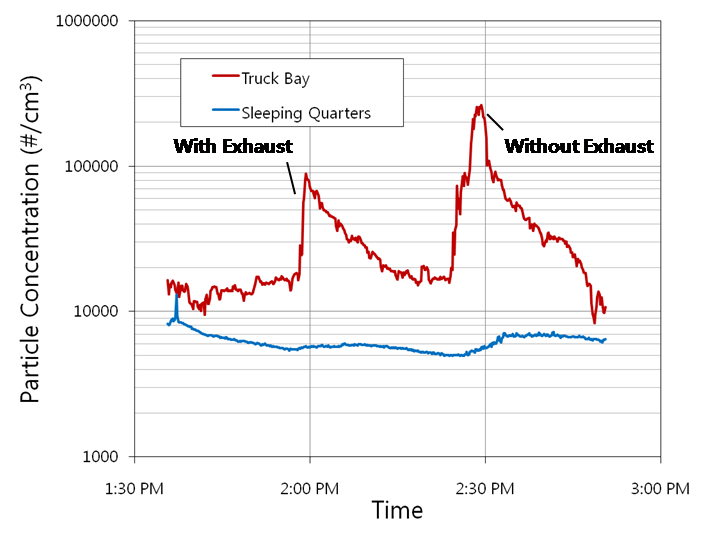

The graph below shows the time-resolved particle concentrations on a log scale measured in the two locations, first with the exhaust system operating and second with the exhaust system disconnected. In both cases, you can see a spike in particle concentrations in the truck bay after the truck pulls back into the station. Sleeping quarter concentrations were not affected as much.

Figure 1. Time-resolved submicron particle concentrations in the fire station w/ and w/out an exhaust system operating. Blue line = sleeping quarters; Red line = truck bay.

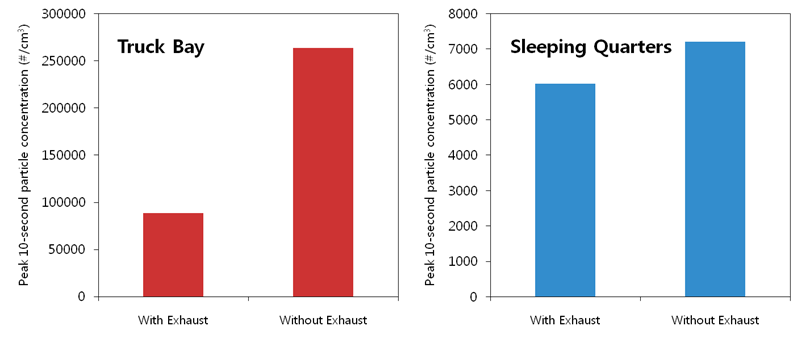

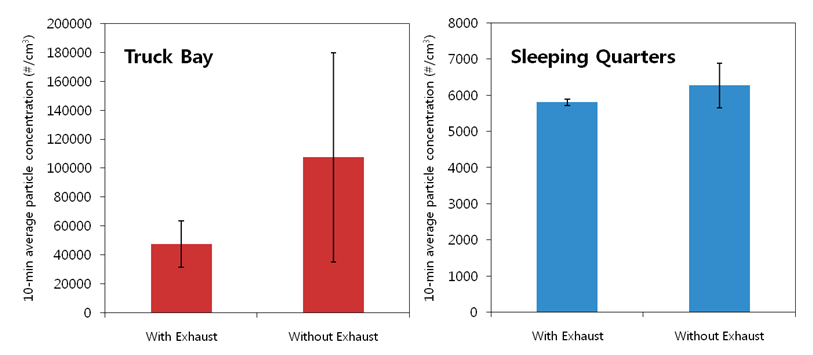

Figure 2 and Figure 3 shows the peak 10-second and 10-minute average (+/- std. dev.) concentrations measured in each location, respectively, with and without the exhaust system running.

Figure 2. Peak 10-second particle concentration with and without the exhaust system operating: (a) in the truck bay and (b) in the sleeping quarters.

Figure 3. Ten-minute average (+/- std. dev.) particle concentrations with and without the exhaust system operating: (a) in the truck bay and (b) in the sleeping quarters.

As you can see, the exhaust system works quite well in terms of reducing particle exposures in the truck bay. Peak particle concentrations in the bay were nearly 200% higher without the exhaust system operating; 10-min average concentrations were still more than double without the exhaust system operating. Despite the relative differences, it is important to note that there is still a large absolute increase in number concentrations even with the exhaust system operating, likely stemming from the engine idling just outside of the open truck bay.

Differences in sleeping quarters concentrations were much lower, as particles would have to rise from the lower truck bay through leakage in the ceiling and into the sleeping area. There was still a small difference, however. Peak 10-second concentrations in the sleeping area were approximately 20% higher without the exhaust system operating compared to the exhaust-off case. 10-minute average concentrations were about 8% lower.

So, overall, the exhaust system is clearly much preferred to a no-exhaust condition and these ventilation systems appear to do a good job reducing firefighters’ exposures to diesel exhaust.

Filed under: Exposure measurement | Particulate matter